WP5 objectives

The aim of the demonstration activities in Escombreras is to readapt the current fertilizer production process in QSr (currently producing KNO3, Ca(NO3)2, Mg(NO3)2, Sr(NO3)2, SrCO3, (NH4)2SO4 and NH4NO3) to replace imported raw material (HCl and CaCO3), utilize CO2 from surrounding industries and reduce wastewater discharge and water consumption.

Other aims include the reduction of wastewater problem and improvement in the management of common water infrastructure as well as the reduction of the overall CO2 emissions at park level. Moreover, the WP also aims to achieve direct reduction of raw material and water consumption at local level and at industrial group level (Grupo Fertiberia) as well as work on the design of a CSP Plant for maximizing its supply efficiency and decarbonize the energy supply of the industrial area.

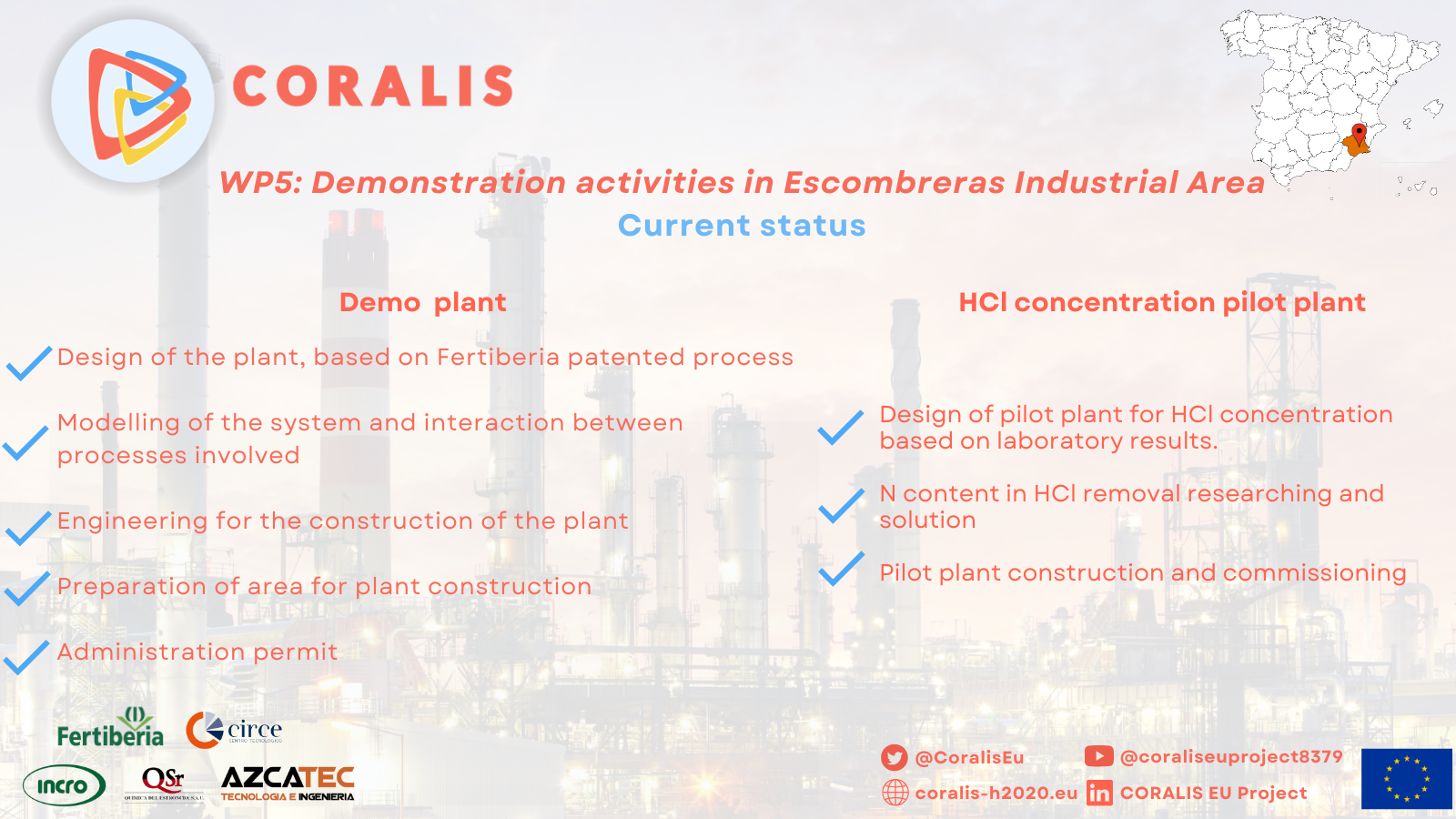

WP5 status

The work is at the final stages. What has been done so far is:

Modelling activities:

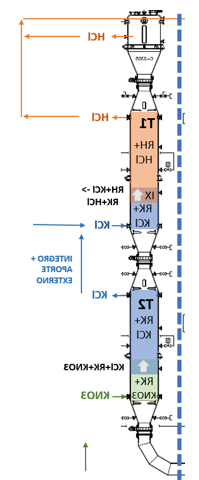

- Modelling of the system and interaction between processes involved.

- Modelling of the HCl concentration.

- Modelling of denitrification of HCl (not finished).

Figure 1: Reactor model

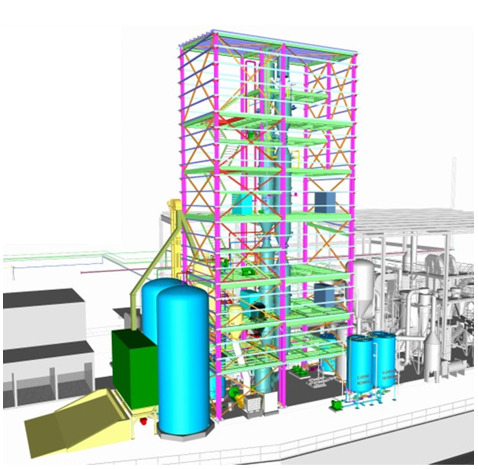

Figure 2: 3D plot plan

For demo plant activities:

- Scaling up of the demo plant, based on patented pilot plant result, previous to CORALIS project.

- Design of demo plant.

- Basic engineering of demo plant.

- Safety

- Detail engineering of demo plant.

- Solution of found problems such as:

- Lack of instrumentation on the market to control the reactions (selective electrodes). It was solved selecting an instrument based on redox properties of ions. Another problem arose: the selected instrument was developed by Ukrainian technician and due to the Russia-Ukraine war, they could not be available for some time.

- Problems finding the appropriate valves for the Demo capacity.

- Pandemic and Energy crisis produced important delays and high material prices that jeopardized the project. Partners decided to reduced installation to 50%, and so capacity of the plant, what improved material and equipment availability in the market, for example valves sizes.

- Permits from the Authorities were difficult to get on time, but they could be got due to the formal Potassium Nitrate Plant permit extension.

For HCl concentration pilot plant activities:

- Design of the plant based on laboratory results for the HCl concentration.

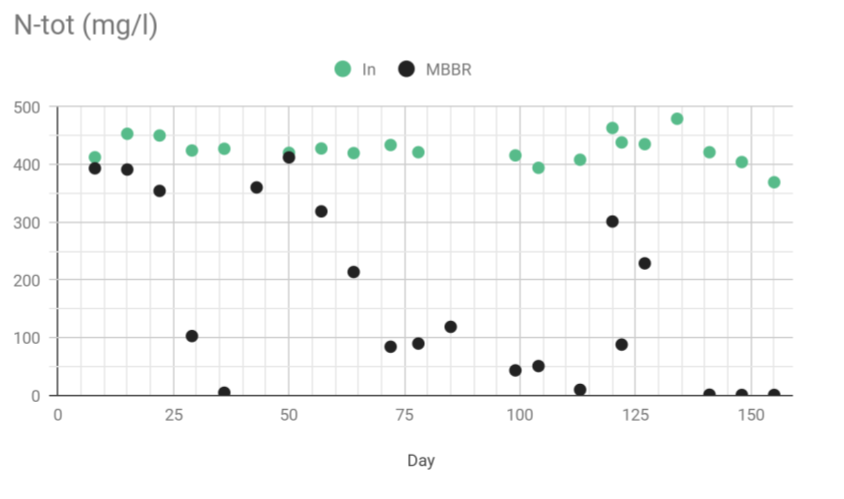

- N content of the HCl from the Demo plant was necessary to remove in order to recover this by-product. Fertiberia and partners worked on different technologies to remove Nitrogen

- A technology that was tested for the removal of N from HCl solution was based on a novel catalyst. Many problems arose using the mentioned catalyst, such as corrosion problems in the pilot, short lifetime, difficulties in catalyst recycle, unexpected results, etc. These problems led to the catalyst being discarded.

- Fertiberia and partners tested a new technology for the N removal in the wastewater from lixiviation with HCl by-product. The biological treatment results are very good for N-removal, even at high salinity.

- The design of the concentration system and the Basic Engineering are finished and the pilot plant installed. N in CaCl2 will be removed using bio-treatment.

- Purchase, commissioning and installation are finished. A testing plan is designed to start with the testing.

Figure 3: Pilot plant for catalyst N-removal.

Figure 4: Result from Bio-treatment in the pilot for N-removal.

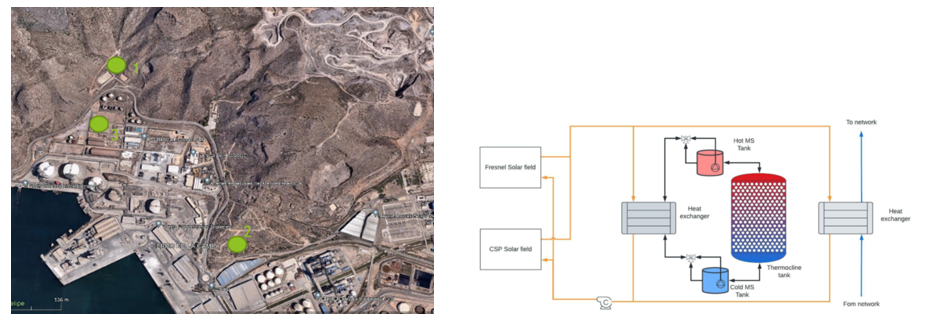

For the techno-economic analysis of the CSP Plant:

- Technology has been selected based on available field, efficiency and needed power: Solar Tower

- Study of available solar fields to install CSP.

- General CSP simulation program was used for calculations.

- Separate Simulation of tank (thermocline), using Fertiberia’s salt formulations. This tank will store thermal energy for a minimum of 8 hours.

Figure 5: Available fields for CSP plan in Escombreras area and thermocline technology for thermal energy storage.

For more details, check out:

D5.1 Detailed characterization and validation models of main processes (CO)

D5.2 ROM for CORALIS platform (CO)

D5.3 Construction of KNO3 reactor (CO)

D5.4 Construction of HCl Concentration System (CO)

WP5 next steps

The next steps for the WP5 are:

- Modelling of the system and interaction between processes involved will continue to adapt results to models.

- The Demo plant engineering is finished and construction is in purchasing process.

- N-removal system is decided, engineering of the pilot is finished, construction is done. Tests will start in short.

- Once Permits are received and installation area is prepared, new structure will be built to start plant installation.

- The study for the CSP Plant integration at Escombreras industrial area will be finished in short and a report will be issued.

Figure 6: existing structure dismantling for installation of Demo plant.