Lighthouse: Escombreras Valley

Cartagena (Murcia), Spain

Main drivers to join the project

Sectors involved

Stakeholders

Resources

Annual energy use

MWh/year

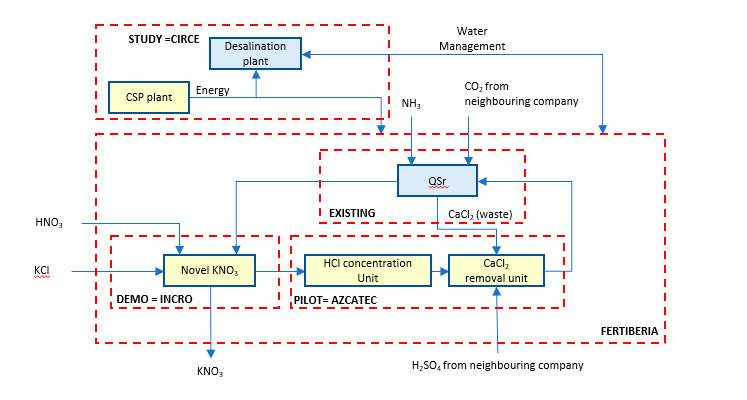

Overall concept of the demonstration activities to be implemented

Creation of new value chains for fertilizer and industrial production

The aim is to readapt the current fertilizer production process in QSr (currently producing KNO3, Ca(NO3)2, Mg(NO3)2, Sr(NO3)2, SrCO3, (NH4)2SO4 and NH4NO3) to replace imported raw material (HCl and CaCO3), utilise CO2 from surrounding industries and reduce waste water discharge and water consumption.

Currently, fertilizers and strontium derivates are produced in parallel processes in the same facility in QSr. First, the strontium mineral is leached with HCl to purify SrSO4.

As a result of the leaching process, wastewater with high concentration of CaCl2 is produced, which reacts with the sulphates discharged upstream, generating CaSO4 which causes severe plugs in the pipeline infrastructure.

This SrSO4 is fed into a set of carbonation reactors working with NH3 and CO2 imported from a nearby industry (“Ecocarburantes Españoles”) to produce SrCO3, obtaining (NH4)2SO4 and NH4NO3 as by-products. Additionally, KNO3 is produced by reacting NH4NO3 and KCl.

NH4Cl is obtained as a by-product, which has little market demand. In parallel, Ca(NO3)2 is obtained by direct reaction of HNO3 and CaCO3, emitting CO2 in the process.

The demonstration action will pivot around a novel KNO3 process as depicted in the Figure above, developed by Fertiberia.

This process will use HNO3 and KCl as raw materials, obtaining diluted HCl, which will be neutralized and mixed with the CaCl2-containing water from the leaching process.

The CaCl2 solution will be concentrated and treated with H2SO4 (by-product from a nearby industry (“Aemedsa”)) to produce concentrated HCl (30%) and CaSO4, thus eliminating the CaCl2 and reducing wastewater. This wastewater treatment process will be tested in a pilot plant in QSr. The demo plant for the new KNO3 process will be installed in QSr.

Concentrated HCl can be then reused in the leaching process while the CaSO4 can be recovered for two purposes: 1) part can be fed into some of the carbonation reactors to produce CaCO3, which replaces mineral-based CaCO3 for the Ca(NO3)2 production, reducing overall CO2 emissions in the park; and 2) to produce Ammonia Nitrate + S, which is currently obtained in other Fertiberia plant located in Sagunto, which uses carbonate and gypsum from mines. Hence, the process to be demonstrated in Escombreras will indirectly reduce CO2 emissions of Fertiberia group.

Energy efficiency

Energy intensity

CO2 emissions

Raw materials intensity

Waste generation (CaCl2)

Techno-economic assessment of the implementation of a CSP plant

CORALIS will study the technical and economic feasibility for the implementation of at least 4-MW CSP Plant at industrial area level. This project is under planning and is expected to start in 2021, so CORALIS will provide the basis for the facility design and interaction with Escombreras.

The CSP will produce steam at high pressure, supported by a molten salt storage developed and patented by Fertiberia.

This HP steam will be fed into a steam turbine, that will produce low pressure steam to cover the energy needs of QSr processes and mechanical energy into a water closed-circuit to provide mechanical energy to the desalination plant.

The study will also consider the assessment for the design of the plant in order to supply energy to the rest of industries at the Escombreras Valley Area.

In order to facilitate the implementation of the CSP plant, the new process demonstrated in QSr will be tested under variable steam pressure conditions, simulating a potential scenario of low-RES generation.

Description of the demonstration readiness level towards Industrial Symbiosis (IS)

Main challenges to be addressed and barriers to be overcome

The main challenges of this demonstration are:

Equipment to be installed, modifications required and relevant activities for each stakeholder involved

Fertiberia

Coordination and direction of the demonstrator. Calculation, simulation and predesign of KNO3 demo plant and HCl concentration system pilot plant. Replication assessment in other plant of the group. Support to the impact analysis (CO2 and raw material reduction) in other plants of the group.